Munyika inogara ichishanduka yekugadzira, kushandura CNC machining zvikamu zviri kutungamira shanduko. Nemaindasitiri anoda kunyatsojeka, kunyatsoita, uye kugadzirisa, tekinoroji yeCNC (Computer Numerical Control) yave yakakosha, kunyanya mukushandura mashandiro. Aya akagadzirwa zvine hungwaru mativi ari kupa simba zvese kubva kumota injini kusvika kune aerospace zvikamu, zvichiita kushandura CNC machining zvikamu dombo repakona rekufambira mberi kwemaindasitiri.

Asi nei zvikamu izvi zvakakosha, uye zviri kutsanangura sei kugadzira? Ngationgororei kuti kushandura CNC machining kuri kuseta mabhenji matsva ekunyatso, kuita, uye kugona kugadzira.

Chii chiri Kushandura CNC Machining Zvikamu?

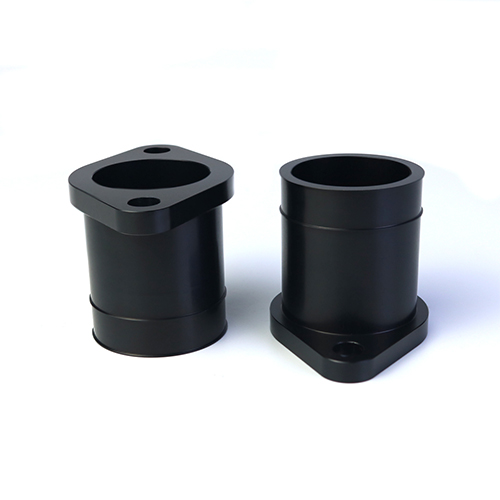

Pakati payo, kushandura CNC machining kunosanganisira kubvisa zvinhu kubva kune inotenderera workpiece kugadzira chaiyo cylindrical maumbirwo. Iyi nzira inoitwa pachishandiswa yakanyanya advanced CNC lathes, ayo akarongerwa kuburitsa zvikamu zvine huchokwadi uye kuenderana.

Mienzaniso yakajairwa yekutenderedza CNC machining zvikamu zvinosanganisira shafts, bushings, spindles, screws, uye flanges, izvo zvese zvinoda kurongeka kwepamusoro kuti ive nechokwadi chekuita pasina musono mumashandisirwo azvo.

Kusiyana nemaitiro echinyakare ekutendeuka, CNC michina inogona kugadzira zvikamu zvine micron-level kushivirira, zvichiita kuti zvive zvakanakira maindasitiri uko kunyangwe kutsauka kudiki kunogona kukanganisa kuita, senge aerospace, zvigadziriso zvekurapa, mota, uye zvemagetsi.

Nei Kushandura CNC Machining Zvikamu Zvichichinja

1. Kururamisa Kusingaenzaniswi

Precision ndicho chiratidzo chekushandura CNC machining. Mazuva ano CNC lathes akashongedzerwa nekucheka-kumucheto software uye maturusi anoita kuti vagadziri vagadzire zvikamu zvine hunyoro hunoshamisa.

Semuyenzaniso, zvinhu zvemuchadenga zvakaita sematurbine shafts kana maimplants ekurapa semabhonzo screws zvinoda geometry yakakwana kuti iite sezvakarongwa. CNC kutendeuka kunoita kuti zvinhu izvi zvisangane neyakaomesesa mhando zviyero, kubvisa njodzi dzine chekuita nezvikanganiso zvemanyorero.

2. Kuwedzera Kubudirira Kwekugadzira

CNC inoshandura michina inoshanda nekumhanya kwakanyanya uku ichichengetedza kuenderana kune yakakura kugadzirwa inomhanya. Kusiyana nemazino emaoko, ayo anoda kugara achitariswa nevanhu, CNC lathes inogona kumhanya yakazvimiririra, ichideredza zvakanyanya nguva yekugadzira uye mutengo wevashandi.

Kune maindasitiri anogadzira mavhoriyamu makuru ezvikamu zvakashandurwa, senge mota kana maindasitiri muchina, CNC tekinoroji inobvumira kukurumidza, inodhura-inoshanda kugadzira pasina kupira mhando.

3. Enhanced Customization

Iko kuchinjika kweCNC machining inobvumira vagadziri kugadzira zvikamu zvetsika zvakagadzirirwa kune chaiwo maapplication. Iine advanced CAD/CAM software, mainjiniya anogona kugadzira akaomarara geometries uye oashandura zvakananga muCNC zvirongwa.

Ingave iri-imwe-imwe prototype kana batch yezvikamu zvetsika zveinjini-inoshanda, CNC kutendeuka kunopa isingaenzaniswi dhizaini rusununguko. Izvi zvinonyanya kukosha muzvikamu senge motorsports uye zvinhu zveumbozha, uko akasiyana, epamusoro-kuita zvikamu zviri kudiwa zvakanyanya.

4. Superior Material Compatibility

CNC inoshandura michina inogona kubata zvakasiyana-siyana zvezvinhu, kubva kumatare echinyakare sealuminium, simbi, uye ndarira, kusvika kune epamusoro alloys uye macomposites setitanium uye kabhoni fiber.

Izvi zvakasiyana-siyana zvinoita kuti vagadziri vakwanise kusangana nezvinodiwa zvakasiyana-siyana zvemaindasitiri anoda zvinhu zvine zvinhu zvakati tsvikiti, senge zviremera zvemuchadenga kana ma implants ekurapa asingadziviriri.

Zvikumbiro Kutyaira Kuda Kushandura CNC Machining Zvikamu

1.Automotive Industry

Kushandura CNC machining zvikamu kwakakosha muchikamu chemotokari, kugadzira zvinhu zvakakosha senge injini pistons, giya shafts, uye zvinhu zvekutungamirira. Iko kurongeka uye kusimba kweCNC-yakatenderedzwa zvikamu zvinovimbisa kuita kwakaringana kwemotokari, kushanda zvakanaka, uye kuchengetedzeka.

2.Aerospace Engineering

Muchadenga, hapana nzvimbo yekukanganisa. CNC-yakatenderedzwa zvikamu senge zvisungo zvendege, magiya ekumhara, uye turbine shafts anogadzirwa kuti aite zvakatemerwa kuti asangane nekuomarara kwenzvimbo dzekubhururuka.

3.Mishonga Yezvokurapa

Indasitiri yezvokurapa inovimba zvakanyanya neCNC machining yekugadzira maturusi ekuvhiya, maimplants, uye prosthetics. Kushandura CNC machining kunovimbisa kuti zvikamu izvi hazvisi chete chaizvo asiwo biocompatible uye yakachengeteka kuti ishandiswe mune zvine hunyanzvi maapplication.

4.Electronics

Kubva madiki madiki kusvika kune ekupisa sinks, CNC kutendeuka kunoita basa rakakosha muindasitiri yemagetsi. Kugona kushanda nezvinhu zvakapfava uye kugadzira zvidiki, zvakaomarara zvikamu zvakaita kuti CNC ishanduke ive yakakosha mundima iyi.

Tekinoroji Kufambira mberi muCNC Kutendeuka

Munda weCNC kutendeuka uri kubuda nekukurumidza, nehunyanzvi hunowedzera kukurumidza, huchokwadi, uye kushanda:

1. Multi-Axis CNC Lathes

Mazuva ano CNC lathes ikozvino inoratidzira akawanda-axis kugona, zvichiita kuti yakaoma geometries kugadzirwa mune imwechete setup. Izvi zvinobvisa kudiwa kwechipiri mashandiro, kuderedza nguva yekugadzira uye mutengo.

2. IoT Integration

Smart CNC michina yakashongedzerwa neIoT sensors inobvumira chaiyo-nguva yekutarisisa kwemachining mashandiro, kuve nechokwadi chekutonga kwemhando uye kufungidzira kugadzirisa.

3. Advanced Cutting Tools

Iko kuvandudza kwepamusoro-inoshanda kucheka maturusi, akadai sedhaimondi-yakaiswa muromo kana yakavharidzirwa carbide inoisa, yakavandudza machining kushanda uye yakawedzera hupenyu hwematurusi, kunyangwe kana uchishanda nezvinhu zvakaomarara setitanium kana Inconel.

Ramangwana reKushandura CNC Machining Zvikamu

Sezvo maindasitiri achiramba achida kunyatsojeka uye kushanda nesimba, kushandura CNC machining kuchaita basa rinowedzera kukosha. Iko kubatanidzwa kwehungwaru hwekugadzira uye otomatiki yakagadzirira kuita CNC inoshandura michina iwedzere kungwara uye inokwanisa, ichibvumira hukuru hukuru uye nekukurumidza kutenderera kutenderera.

Zvakare, nekusundidzira kune kusimudzira, CNC machining iri kutora eco-hushamwari maitiro, senge kudzikisa tsvina yezvinhu kuburikidza neakagadziridzwa machining maitiro uye kushandisa zvinhu zvinodzokororwa.

Mhedziso: Kushandura CNC Machining Zvikamu seCatalyst yekufambira mberi

Kusimuka kwekutendeuka kweCNC machining zvikamu zvinomiririra kusvetuka kwakakosha kumberi kwemaindasitiri ekugadzira. Nekubatanidza kurongeka, kunyatsoita, uye kuita zvinhu zvakasiyana-siyana, zvikamu izvi zviri kufambisa hunyanzvi pane dzakasiyana siyana dzekushandisa, kubva pakufambisa uye kutarisisa hutano kusvika kune tekinoroji nekudzivirira.

Sezvo tekinoroji yeCNC ichienderera mberi, mikana yekushandura CNC machining zvikamu haina magumo. Kune vagadziri vanovavarira kuramba vachikwikwidza munyika iri kukurumidza kuchinja, kuisa mari mukucheka-kumucheto CNC kutendeuka kugona haisi sarudzo chete-icho chinhu chinodiwa.

Kunyangwe ichigonesa mota dzechizvarwa chinotevera, ichigonesa kuponesa hupenyu michina yekurapa, kana kugadzira zvemagetsi zveramangwana, kushandura CNC machining zvikamu zviri pamberi mukugadzira kwakaringana muzana remakore rechi21.

Nguva yekutumira: Jan-06-2025