PFT, Shenzhen

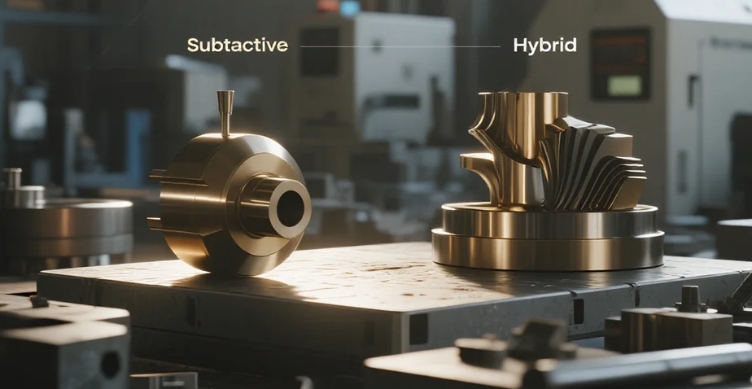

Ichi chidzidzo chinoenzanisa kushanda kwechinyakare kubvisa CNC machining neinobukira hybrid CNC-Additive Manufacturing (AM) yekugadzirisa maturusi eindasitiri. Performance metrics (nguva yekugadzirisa, kushandiswa kwezvinhu, simba remuchina) zvakaverengerwa pachishandiswa zviedzo zvinodzorwa pane zvakakanganisika chitambi chinofa. Mhedzisiro inoratidza nzira dzakasanganiswa dzinodzikisa tsvina yezvinhu ne28-42% uye kupfupisa magadzirirwo ekugadzirisa ne15-30% maringe nekubvisa-chete nzira. Kuongororwa kwe Microstructural kunosimbisa kuenzana kwesimba rekusimba (≥98% yechishandiso chepakutanga) muzvikamu zvakasanganiswa-zvakagadziridzwa. Iyo yekutanga miganho inosanganisira geometric kuomarara zvipingaidzo zve AM deposition. Izvi zvakawanikwa zvinoratidza hybrid CNC-AM senzira inogoneka yekuchengetedza maturusi ekugadzirisa.

1 Nhanganyaya

Kushatisa kwemidziyo kunodhura maindasitiri ekugadzira $240B pagore (NIST, 2024). Traditional subtractive CNC kugadzirisa inobvisa zvikamu zvakakanganisika kuburikidza nekugaya / kugaya, kazhinji kurasa > 60% yezvinhu zvinoponeswa. Hybrid CNC-AM kubatanidzwa (yakananga simba kuisa pane iripo chishandiso) inovimbisa kushanda zvakanaka kwesosi asi inoshaya kusimbiswa kwemaindasitiri. Tsvagiridzo iyi inoverengera mabhenefiti ekushanda kweiyo hybrid workflows maringe neyakajairwa nzira dzekubvisa dzepamusoro-kukosha maturusi kugadzirisa.

2 Nzira

2.1 Kuedza Dhizaini

Vashanu vakakuvadzwa H13 simbi yekutsikitsira inofa (zviyero: 300 × 150 × 80mm) yakaitwa maviri ekugadzirisa mapuroteni:

-

Boka A (Kubvisa):

-Kubvisa kukanganisa kuburikidza ne5-axis milling (DMG MORI DMU 80)

- Welding filler deposition (GTAW)

- Pedzisa machining kune yekutanga CAD -

Boka B (Hybrid):

-Kubvisa chirema kudiki (<1mm kudzika)

- DED kugadzirisa uchishandisa Meltio M450 (316L waya)

- Adaptive CNC remachining (Siemens NX CAM)

2.2 Kuwana Data

-

Kushanda Kwezvinhu: Misa zviyero pre/post-kugadzirisa (Mettler XS205)

-

Nguva yekutevera: Maitiro ekutarisa neIoT sensors (ToolConnect)

-

Mechanical Testing:

- Kuoma mepu (Buehler IndentaMet 1100)

- Tensile samples (ASTM E8/E8M) kubva kunzvimbo dzakagadziriswa

3 Mhinduro & Analysis

3.1 Resource Utilization

Tafura 1: Kugadzirisa Maitiro Metrics Kuenzanisa

| Metric | Subtractive Repair | Hybrid Repair | Kuderedza |

|---|---|---|---|

| Kushandiswa Kwezvinhu | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Active Kugadzirisa Nguva | 14.2 awa ± 1.1 awa | 10.1 awa ± 0.8 awa | 28.9% |

| Kushandiswa Kwesimba | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Mechanical Kutendeseka

Mienzaniso yeHybrid-yakagadziridzwa inoratidzwa:

-

Kuomarara kunoenderana (52–54 HRC vs. yepakutanga 53 HRC)

-

Simba rekupedzisira rekusimba: 1,890 MPa (± 25 MPa) - 98.4% yezvinhu zvepasi

-

Hapana interfacial delamination mukuedza kuneta (10⁶ mitsetse pa80% goho kushushikana)

Mufananidzo 1: Microstructure ye hybrid kugadzirisa interface (SEM 500 ×)

Cherechedza: Equiaxed zviyo chimiro pamuganho wefusion inoratidza kutonga kunoshanda kwekupisa.

4 Kukurukurirana

4.1 Operational Implications

Iyo 28.9% yekuderedza nguva inobva pakubvisa kubviswa kwezvinhu zvakawanda. Hybrid processing inoratidza kubatsira kune:

-

Legacy tooling ine discontinued material stock

-

High-complexity geometries (semuenzaniso, conformal cooling channels)

-

Zviitiko zvekugadzirisa zvishoma

4.2 Technical Constraints

Mipimo inocherechedzwa:

-

Maximum deposition angle: 45° kubva kuhorizontal (inodzivirira kukanganisika kwepamusoro)

-

DED layer ukobvu musiyano: ± 0.12mm inoda adaptive maturusi nzira

-

Post-process HIP kurapwa kwakakosha kune aerospace-giredhi maturusi

5 Mhedziso

Hybrid CNC-AM inoderedza maturusi ekugadzirisa mashandisirwo ekushandisa ne23-42% uku ichichengetedza kuenzana kwemichina kune nzira dzekubvisa. Kuita kunokurudzirwa kune zvikamu zvine mwero geometric kuoma uko kuchengetwa kwezvinhu kunopembedza AM mashandiro emitengo. Tsvagiridzo inozotevera inogonesa nzira dzekuisa masimbi emidziyo yakaoma (> 60 HRC).

Nguva yekutumira: Aug-04-2025