Magnetic vs Pneumatic Workholding yeTin Sheet Aluminium

Munyori: PFT, Shenzhen

Abstract

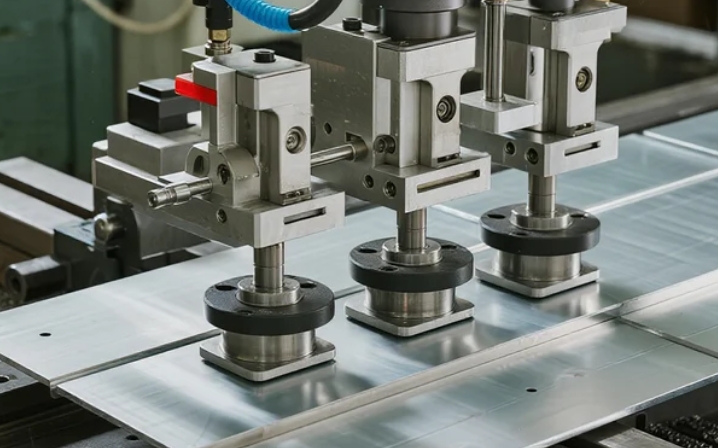

Precision machining yearuminiyamu yakaonda sheet (<3mm) inotarisana nematambudziko makuru ekushanda. Ichi chidzidzo chinofananidza magineti uye pneumatic clamping masisitimu ari pasi peanodzorwa CNC milling mamiriro. Muedzo maparamendi aisanganisira kusimba kwesimba, kugadzikana kwekupisa (20°C–80°C), kunyorovesa, uye kukanganiswa kwepasi. Pneumatic vacuum chucks inochengetedza 0.02mm flatness ye 0.8mm mashiti asi yaida intact yekuvharisa nzvimbo. Electromagnetic chucks yakagonesa 5-axis kuwana uye yakaderedzwa kuseta nguva ne60%, asi yakakandwa eddy currents yakakonzera kupisa kwenzvimbo kunodarika 45°C pa15,000 RPM. Mhedzisiro inoratidza vacuum masisitimu anokwenenzvera kupedzwa kwepamusoro kwemashiti> 0.5mm, nepo magineti mhinduro ichivandudza kuchinjika kwekukurumidza prototyping. Zvipingamupinyi zvinosanganisira nzira dzisina kuedzwa dzakasanganiswa uye adhesive-based dzimwe nzira.

1 Nhanganyaya

Mashizha matete aruminiyamu maindasitiri emagetsi kubva kune aerospace (fuselage matehwe) kune zvemagetsi (kupisa sink yekugadzira). Zvakadaro 2025 ongororo yeindasitiri inoratidza 42% yehurema chaihwo hunobva pakufamba kweworkpiece panguva yekugadzira. Yakajairwa machira machira anowanzo kukanganisa sub-1mm mashiti, nepo tepi-yakavakirwa nzira dzisina kusimba. Ichi chidzidzo chinoverengera mhinduro mbiri dzepamberi: electromagnetic chucks leveraging remanence control tekinoroji uye pneumatic masisitimu ane akawanda-zone vacuum control.

2 Nzira

2.1 Kuedza Dhizaini

-

Zvishandiso: 6061-T6 aruminiyamu mapepa (0.5mm/0.8mm/1.2mm)

-

Equipments:

-

Magnetic: GROB 4-axis electromagnetic chuck (0.8T munda kusimba)

-

Pneumatic: SCHUNK vacuum ndiro ine 36-zone manifold

-

-

Kuedza: Surface flatness (laser interferometer), thermal imaging (FLIR T540), vibration analysis (3-axis accelerometers)

2.2 Test Protocols

-

Static Kugadzikana: Edza kutsauka pasi pe5N lateral simba

-

Thermal Cycling: Rekodha tembiricha gradients panguva slot milling (Ø6mm end mill, 12,000 RPM)

-

Dynamic Rigidity: Quantify vibration amplitude pane resonant frequencies (500-3000 Hz)

3 Migumisiro uye Ongororo

3.1 Clamping Performance

| Parameter | Pneumatic (0.8mm) | Magnetic (0.8mm) |

|---|---|---|

| Avg. Distortion | 0.02mm | 0.15mm |

| Setup Nguva | 8.5 min | 3.2 min |

| Max Temp Rise | 22°C | 48°C |

Mufananidzo 1: Vacuum masisitimu akachengetwa <5μm kushanduka kwepasi panguva yekugaya kumeso, nepo magineti clamping yakaratidza 0.12mm edge kusimudzwa nekuda kwekuwedzera kwekupisa.

3.2 Vibration Hunhu

Pneumatic chucks attenuated harmonics ne 15dB pa 2,200Hz - yakakosha pakupedzisa-kupedzisa mashandiro. Magnetic workholding yakaratidza 40% yepamusoro amplitude pamaturusi ekuita ma frequency.

4 Kukurukurirana

4.1 Technology Tradeoffs

-

Pneumatic Advantage: Superior thermal kugadzikana uye vibration damping sutu yakakwirira-kushivirira zvikumbiro senge optical chikamu mabhesi.

-

Magnetic Edge: Rapid reconfiguration inotsigira basa-shopu nharaunda inobata akasiyana siyana batch saizi.

Limitation: Miedzo isingabatanidzwe ane perforated kana ane mafuta mashiti apo vacuum inoshanda inodonha> 70%. Mhinduro dzeHybrid dzinotendera kudzidza mune ramangwana.

5 Mhedziso

Kune yakaonda aluminium sheet machining:

-

Pneumatic workholding inopa kurongeka kwepamusoro kune ukobvu> 0.5mm ine nzvimbo isina kuchinjika.

-

Magnetic masisitimu anoderedza nguva isiri yekucheka ne60% asi inoda nzira dzekutonhodza dzekutonga kwekupisa

-

Sarudzo yakakwana inotsamira pane zvinodiwa pakupinda maringe nezvinodiwa zvekushivirira

Tsvagiridzo yeramangwana inofanirwa kuongorora adaptive hybrid clamps uye yakaderera-inopindira electromagnet madhizaini.

Nguva yekutumira: Jul-24-2025