Muzuva ranhasi's inokurumidzakugadzira Munyika, mabhizinesi mumaindasitiri akasiyana ari kuramba achivimba netsika machining kuti asangane nekuwedzera kuri kudiwa kwezvinhu zvakagadziridzwa-engineered. Sezvo maindasitiri achishanduka uye magadzirirwo echigadzirwa akawedzera kuomarara, kugona kugadzira zvikamu zvetsika zvine zvirevo chaizvo hazvina kumbonyanya kukosha. Tsika machining inopa inochinja-chinja, inodhura-inoshanda, uye inoshanda mhinduro kumakambani ari kutsvaga emhando yepamusoro, akagadzirwa-akagadzirwa zvikamu zvinoenderana nezvavanoda zvakasiyana.

Kubva mundege kuenda kumidziyo yekurapa, mota kuenda kumagetsi, kudiwa kwezvikamu zvemuchina-tsika kuri kuwedzera. Ichi chinyorwa chinoongorora kuti chii chinonzi tsika machining, nei chiri kuwana traction mumaindasitiri, mabhenefiti aanopa, uye kuti ari kushandura sei mamiriro ekugadzira.

Chii chinonzi Custom Machining?

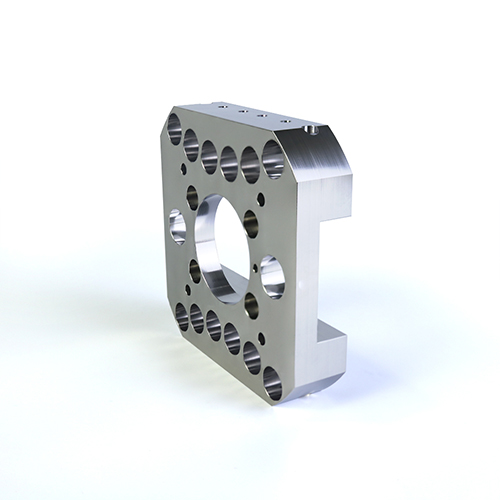

Custom Machining inoreva nzira yekugadzira iyo chidimbu chebasa (chinowanzo gadzirwa kubva kusimbi, purasitiki, kana zvinhu zvinoumbwa) zvakaumbwa, kutemwa, kana kupera kuti zvisangane nehumwe hukuru uye kushivirira. Kusiyana nemaitiro echinyakare, akawanda-akagadzirwa zvinhu, tsika machining inogadzirirwa kune izvo chaizvo zvinodiwa nemutengi, zvichibvumira kuomesesa geometries, kushivirira kwakasimba, uye yepamusoro-mhando kupera.

Kushandisa matekinoroji akadaiCNC(Computer Numerical Control) machining, kugaya, kutenderedza, kukuya, nekuboora, machining ega egagadzira zvikamuyezvakasiyana-siyana zvinoomesesa-kubva pazvimedu zviri nyore, zvinoshanda kusvika kune yakaoma, yakakwirira-chaiyo zvikamu zvemaindasitiri senge aerospace, mota, zvekurapa, nezvimwe.

Nei Tsika Machining Iri Kuwana Mukurumbira

Zvinhu zvakati wandei zvakafambisa kuvimba kuri kukura patsika machining mumaindasitiri. Izvi zvinosanganisira:

●Kuwedzera Kuoma Mukugadzira:Sezvo maindasitiri achisundidzira miganhu yehunyanzvi, magadzirirwo echigadzirwa ari kuwedzera kuoma. Tsika machining inobvumira vagadziri kuti vagadzire zvikamu zvinosangana neakaomeswa, zvichipa kuchinjika kugadzira zvikamu zvine maumbirwo akaomarara, macurves, uye akadzama maficha angave akaoma kana kusagoneka kuwana kuburikidza nemaitiro echinyakare-yekugadzira nzira.

● Hunhu Hwakasiyana-siyana:Kugadzirwa kwetsika kwakakodzera kune zvakasiyana siyana zvemidziyo, kubva kusimbi (sealuminium, simbi isina tsvina, uye titanium) kusvika kumapurasitiki (senge polycarbonate nenylon) nemacomposites. Izvi zvakasiyana-siyana zvinobvumira vagadziri kuti vasarudze zvinhu zvakanakisa zvekushandisa kwavo chaiko, kungave kwakareruka, kusimba, kana corrosion-resistant.

● Kunyatsorongeka uye Kushivirira:Imwe yemabhenefiti ekutanga etsika machining kugona kuwana kushivirira kwakasimba (kunyatso ± 0.001 inches kana pasi). Mumaindasitiri akaita semidziyo yekurapa, aerospace, uye zvemagetsi, kunyatsoita kwakakosha. Tsika machining inova nechokwadi chekuti chikamu chese chinokwana zvakakwana uye chinoshanda nekuvimbika, kunyangwe mumishini-yakakosha maapplication.

● Kugadzirwa Kusingadhuri Kwakaderera-Volume:Nepo nzira dzekugadzira dzepamusoro-soro senge jekiseni rekugadzira kana kufa-kukanda kazhinji dzinoda kudhura maturusi uye mold, tsika machining inogona kudhura-inoshanda kune yakaderera kusvika pakati pekugadzira inomhanya. Sezvo zvisingade kugadzirwa kwezvishandiso zvine hunyanzvi, mitengo inodyidzana netsika machining inowanzodzika, kunyanya yeprototyping kana diki kugadzirwa kwebatch.

● Rapid Prototyping uye Iteration:Tsika machining ndiyo yakanakira mhinduro yekukurumidza prototyping. Mainjiniya anogona kukurumidza kugadzira prototype, kuiyedza, uye kudzokorora dhizaini pasina kunonoka kana mutengo. Iyi agility inomhanyisa maitiro ekusimudzira uye inoderedza nguva-ku-musika kune zvigadzirwa zvitsva.

Custom Machining Inoshanda Sei?

Iyo tsika machining process inosanganisira akati wandei matanho akakosha, rimwe nerimwe rakanangana nekuona kuti chikamu chekupedzisira chinosangana nemadimikira chaiwo akataurwa nemutengi:

● Chikamu Chekugadzira:Nhanho yekutanga mukugadzira machining ndiko kusikwa kweiyo chaiyo dhizaini. Izvi zvinowanzoitwa uchishandisa CAD (Computer-Aided Design) software, iyo inobvumira mainjiniya nevagadziri kugadzira 2D kana 3D modhi yechikamu. Iyo CAD dhizaini inozoshandurwa kuita kodhi inoverengeka muchina, kazhinji muchimiro cheG-code.

● Kusarudzwa kwezvinhu:Zvichienderana nebasa rechikamu uye izvo zvinodiwa zveprojekiti, iyo yakakodzera zvinhu inosarudzwa. Zvishandiso zvakajairika zvinosanganisira simbi sesimbi isina simbi, aluminium, titanium, nendarira, pamwe nemapurasitiki einjiniya seDelrin, Nylon, uye PTFE. Zvishandiso zvine hunhu chaihwo senge kupisa kupisa, conductivity, kana corrosion resistance zvinosarudzwa zvichibva pane zvakarongwa.

● Machining Process:Uchishandisa CNC muchina, zvinhu zvacho zvinochekwa, kuumbwa, uye kupera. Muchina weCNC unotevera mirairo yeG-code kuita mabasa akasiyana siyana, anosanganisira kugaya, kutenderedza, kuchera, kana kukuya. Muchina uyu unogona kuve nematemo akawanda ekufamba (kazhinji 3, 4, kana 5 mbezo) kubvumira yakaoma, yakawanda-dimensional kucheka uye kuumbwa.

● Post-Processing:Mushure mekugadzirwa kwekugadzira, mamwe matanho ekupedzisa anogona kudiwa, senge deburring (kubvisa mipendero yakapinza), polishing, kana kupfeka. Aya emashure-ekugadzirisa matanho anobatsira kuzadzisa inodiwa pamusoro pekupedzisira uye kugadzirisa chitarisiko chechikamu uye kushanda.

● Kudzora Hunhu:Kudzora kwehunhu chinhu chakakosha chetsika machining. Zvikamu zvinoongororwa kuona kuti zvinosangana nezvinodiwa uye kushivirira. Izvi zvinogona kusanganisira kuongorora kwekuona, kuyerwa kwedimensional uchishandisa maturusi akaita seCMM (Coordinate Measuring Machines), uye kuyedza kusimba, kusimba, uye zvimwe zvinoshanda.

● Delivery:Kana chikamu chikapfuura kutonga kwehutano, yakagadzirira kuendeswa kune mutengi. Iko kukurumidza kutendeuka uye kuchinjika kwetsika machining inovimbisa kuti vagadziri vanogona kusangana nemazuva ekupedzisira ekugadzira.

Mabhenefiti Akakosha eCustom Machining

Tsika machining inopa huwandu hwezvakanakira, zvichiita kuti ive sarudzo inosarudzika kune mabhizinesi anotarisa kuburitsa emhando yepamusoro, yakanyatso-engineered zvikamu.

● Kuchinjika Mukugadzira uye Kugadzira:Tsika machining inogona kubata akasiyana siyana ekugadzira uye zvigadzirwa, zvichiita kuti ive yakanyanya kuchinjika yekugadzira maitiro. Kunyangwe iwe uchida chikamu chakareruka kana yakanyanya kuomarara, yakawanda-inoratidzwa chikamu, tsika machining inogona kugadzirisa zvaunoda.

● Kururama uye Kururama:CNC machining inopa kurongeka kusingaenzaniswi, zvichiita kuti ive yakanakira maapplication uko chikamu chega chega chemirimita chinoverengerwa. Zvikamu zvinogadzirwa kuburikidza netsika machining zvinogona kuwana kushivirira kwakasimba se ± 0.001 inches, kuve nechokwadi chekuti chigadzirwa chekupedzisira chinokwana zvakakwana uye chinoshanda sezvakarongwa.

● Dzinodhura-Kushanda paMimhanzi Yakaderera-Volume:Kune maindasitiri anoda mabheti madiki kana zvikamu zvetsika, machining echinyakare anogona kuve mhinduro inodhura kupfuura nzira dzekugadzira dzechinyakare. Kushaikwa kwemitengo yekumberi yekushandisa uye kugona kukurumidza kugadzirisa magadzirirwo ekuchinja kana kugadzirisa kunoita kuti ive mhinduro yakanaka kune yakaderera kusvika pakati pekugadzira inomhanya.

● High-Quality Surface Finishes:Tsika machining inogona kuwana yakanakisa kupedzisa kwepamusoro, iyo yakakosha kune zvese kutaridzika uye kushanda kwezvikamu. Matanho ekumashure-ekugadzirisa senge kukwenenzvera, kupeta, uye anodizing anogona kushandiswa kusimudzira zvimiro zvezvikamu, kuve nechokwadi kuti zvinosangana zvese zvekunaka uye kuita zvinodiwa.

● Kuchinja Nekukurumidza:Iko kugona kukurumidza kugadzira prototypes kana kugadzirwa-yakagadzirira zvikamu kunoita kuti tsika machining ive yekuenda-kune sarudzo yemabhizinesi anoda kuderedza nguva-kumusika. Kana dhizaini yapera, CNC michina inogona kutanga kugadzira zvikamu nekukurumidza, ichipfupisa zvakanyanya kutenderera kwekusimudzira.

Maindasitiri Anobatsirwa neCustom Machining

● Muchadenga:Tsika machining yakakosha mukugadzira aerospace, uko zvikamu zvinofanirwa kusangana nekuchengetedza kwakasimba uye maitiro ekuita. Zvikamu zveinjini, mabhuraketi, magiya ekumhara, uye mashizha eturbine anowanzo kugadzirwa-muchina kuti asangane nezvinodiwa zveindasitiri yemuchadenga.

● Zvishandiso Zvekurapa:Mundima yekurapa, machining echivanhu anoshandiswa kugadzira zvinhu senge maturusi ekuvhiya, ma implants, uye prosthetics. Zvikamu izvi zvinoda kurongeka kwepamusoro uye kazhinji zvinofanirwa kuve biocompatible kana kusagadzikana kune ngura uye kupfeka.

● Motokari:Tsika machining inoshandiswa kugadzira akakosha emotokari zvinhu zvakaita sezvikamu zveinjini, mabhureki, kumiswa zvinhu, uye zvemukati zvikamu. Machining inobvumira kurongeka kwepamusoro uye kusimba, izvo zvakakosha pakuchengetedza motokari uye kuita.

● Zvemagetsi:Indasitiri yemagetsi inovimba netsika machining yezvikamu zvakaita seakavharirwa, zvinobatanidza, uye kupisa sinks. Izvi zvikamu zvakakosha pakuchengetedza midziyo yemagetsi inonzwisisika uye kuve nechokwadi chekuita kwakavimbika.

● Zvishandiso zveindasitiri:Tsika machining inoshandiswa mukugadzira zvikamu zvakaoma zvemichina nemidziyo yemaindasitiri. Ingave iri kugadzira magiya, shafts, kana hydraulic zvikamu, tsika machining inopa iko kurongeka uye kusimba kunodiwa kune maindasitiri maapplication.

Ramangwana reCustom Machining

Ramangwana remuchina wetsika rakajeka, nekufambira mberi mune tekinoroji kuenderera mberi kufambisa indasitiri kumberi. Automation, AI kubatanidzwa, uye zvigadzirwa zvepamberi zvinotarisirwa kuita mabasa akakosha mukuvandudza iko kurongeka, kushanda nesimba, uye kusimudzira.

● AI uye otomatiki:Iko kubatanidzwa kweAI uye kudzidza muchina muCNC machining maitiro kunotarisirwa kusimudzira kugona kwemuchina kuchinjika uye kugadzirisa mashandiro munguva chaiyo, kuwedzera kuvandudza kushanda uye kuderedza nguva.

● Additive Manufacturing Integration:Iko kusanganiswa kwe3D kudhinda (yekuwedzera kugadzira) uye tsika machining iri kutoshandura maindasitiri nekupa yakatokura dhizaini kuchinjika. Hybrid kugadzira maitiro anosanganisa ese machining uye 3D kudhinda ari kuwedzera kuwanda.

● Sustainability:Sezvo kusimba kunova chinhu chakakosha kutarisisa mumaindasitiri, tsika machining icharamba ichishanduka nekusimbisa kudzikisa marara emidziyo uye kushandisa zvinhu zvinodzokororwa kana eco-hushamwari zvinhu.

Nguva yekutumira: Jun-09-2025