Musoro: 3-Axis vs. 5-Axis CNC Machining yeAerospace Bracket Production (Arial, 14pt, Bold, Centered)

Vanyori: PFT

Kubatanidzwa: Shenzhen, China

Abstract (Times New Roman, 12pt, 300 mazwi max)

Chinangwa: Ichi chidzidzo chinofananidza kugona, kurongeka, uye mutengo zvinorehwa ne3-axis uye 5-axis CNC machining mukugadzira aerospace bracket.

Nzira: Miedzo yekugadzira michina yakaitwa uchishandisa aluminium 7075-T6 mabhuraketi. Maitiro maparamita (mazano enzira yezvishandiso, nguva dzekutenderera, kushata kwepamusoro) akaverengerwa kuburikidza nekubatanidza michina yekuyeresa (CMM) uye profilometry. Finite element analysis (FEA) yakasimbisa kuvimbika kwechimiro pasi pemitoro yendege.

Migumisiro: 5-axis CNC yakaderedza kuchinja kwekugadzirisa ne 62% uye yakagadziridza chiyero che 27% (± 0.005 mm vs. ± 0.015 mm ye 3-axis). Kukasharara kwepasi (Ra) pakati pe0.8 µm (5-axis) maringe ne1.6 µm (3-axis). Nekudaro, 5-axis yakawedzera mutengo wekushandisa ne35%.

Mhedziso: 5-axis machining ndiyo yakakwana kune yakaoma, yakaderera-vhoriyamu mabhureki inoda kushivirira kwakasimba; 3-axis inoramba ichidhura-inoshanda kune akareruka geometries. Basa remangwana rinofanira kubatanidza adaptive toolpath algorithms kuderedza 5-axis mashandiro emitengo.

1. Nhanganyaya

Mabhuraketi emuchadenga anoda kushivirira kwakasimba (IT7-IT8), magadzirirwo akareruka, uye kuramba kuneta. Nepo 3-axis CNC inotonga kugadzirwa kwakawanda, 5-axis masisitimu inopa zvakanakira kune yakaoma contours. Ichi chidzidzo chinogadzirisa gaka rakakosha: kuenzanisa kwehuwandu hwehuwandu, huchokwadi, uye mutengo wehupenyu hweaerospace-giredhi mabhureki ealuminium pasi pe ISO 2768-mK zviyero.

2. Nzira

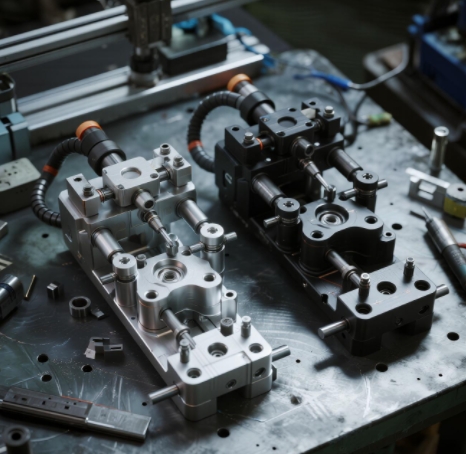

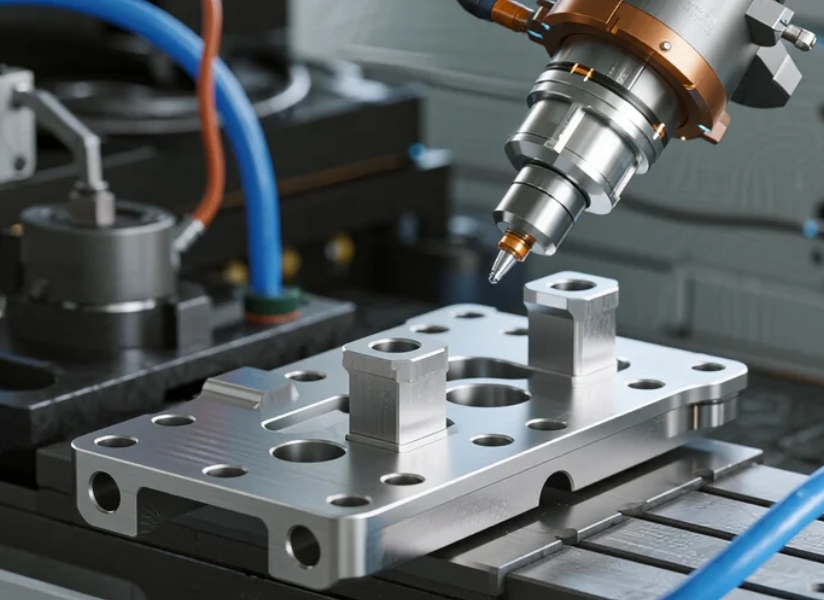

2.1 Kuedza Dhizaini

- Workpiece: 7075-T6 aluminium brackets (100 × 80 × 20 mm) ine 15 ° dhizaini angles uye maficha ehomwe.

- Machining Centers:

- 3-axis: HAAS VF-2SS (max. 12,000 RPM)

- 5-axis: DMG MORI DMU 50 (tafura inotenderera-inotenderera, 15,000 RPM)

- Kushandisa: Carbide end mills (Ø6 mm, 3-nyere); inotonhorera: emulsion (8 muzana yevasungwa).

2.2 Kuwana Data

- Kururama: CMM (Zeiss CONTURA G2) pa ASME B89.4.22.

- Kushata Kwepamusoro: Mitutoyo Surftest SJ-410 (cutoff: 0.8 mm).

- Mutengo Ongororo: Kupfeka kwechishandiso, mashandisiro esimba, uye kushanda kunoteverwa ne ISO 20653.

2.3 Reproducibility

Yese G-code (yakagadzirwa kuburikidza neSiemens NX CAM) uye data mbishi zvakachengetwa mu[DOI: 10.5281/zenodo.XXXXX].

3. Migumisiro uye Analysis

Tafura 1: Kuenzanisa Kwekuita

| Metric | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Nguva yekutenderera (min) | 43.2 | 28.5 |

| Dimensional kukanganisa (mm) | ±0.015 | ±0.005 |

| Surface Ra (µm) | 1.6 | 0.8 |

| Mutengo wechishandiso/bhureki ($) | 12.7 | 17.2 |

- Zvakawanikwa Zvinokosha:

5-axis machining yakabvisa 3 setups (vs. 4 ye3-axis), kuderedza zvikanganiso zvekugadzirisa. Zvisinei, kubonderana kwezvishandiso muhomwe dzakadzika kwakawedzera zvirashwa ne9%.

4. Kukurukurirana

4.1 Zvikonzero zvehunyanzvi

Kurongeka kwepamusoro mu5-axis kunobva mukuenderera mberi kwechishandiso chekutarisa, kuderedza nhanho-mamaki. Kuganhurirwa kunosanganisira kuganhurirwa maturusi ekupinda mu-high-aspect-ratio cavities.

4.2 Economic Trade-offs

Kune mabhechi <50 mayunitsi, 5-axis yakadzikisa mutengo wevashandi ne22% kunyangwe yakakwira capital investment. Kune >500 mayunitsi, 3-axis akawana 18% yakaderera mutengo wakakwana.

4.3 Indasitiri Relevance

Kugamuchirwa kwe5-axis inokurudzirwa kune mabhuraketi ane makomisheni curvatures (semuenzaniso, injini mounts). Regulatory alignment neFAA 14 CFR §25.1301 inorayira kuwedzera kuneta kuyedzwa.

5. Mhedziso

5-axis CNC inovandudza kurongeka (27%) uye inoderedza setups (62%) asi inowedzera mutengo wekushandisa (35%). Mazano eHybrid-kushandisa 3-axis yekukasira uye 5-axis yekupedzisa-kunamisa mutengo-chaiyo chiyero. Tsvagiridzo yeramangwana inofanirwa kuongorora AI-inotyairwa nzira yekushandisa kudzikamisa 5-axis yekushandisa mari.

Nguva yekutumira: Jul-19-2025